With

the rapid development of computer technology, communication technology and

control technology, a series of changes have taken place in the industrial

control network architecture. In recent years, the common trend in the field of

international industrial control is to use the network technology based on IEEE

802.3 and TCP/IP to form a new Ethernet-based network control technology,

namely "Industrial Ethernet." Internationally, the more popular

industrial Ethernets are Ether-NeL/IP, Profinet, Modbus/TCP, HSE, EtherCAT,

PowerLink, EPA, etc.

At

present, there are two development directions for industrial Ethernet: one is

non-standard Ethernet, which has been modified on the basis of Ethernet.

Generally, special chips are used for product development,Profinet is the

typical representative; the other is Standard-based Ethernet enables product

development with industrial Ethernet chips, and EtherNet/IP is a typical

example based on standard Ethernet.

1.Introduction

of EtherNet/IP

The

Common Industrial Protocol (CIP) provides a common application layer and device

description for open fieldbus devices such as DeviceNet, ControlNet, Componet,

and EtherNet/IP. It is built on a single, media-independent platform that

provides seamless communication from the industrial site to the corporate

management layer, enabling users to integrate security, control,

synchronization, motion, messaging and configuration across different networks.

Information. It helps to minimize the overhead of engineering and on-site

installation, allowing users to get the maximum investment income.

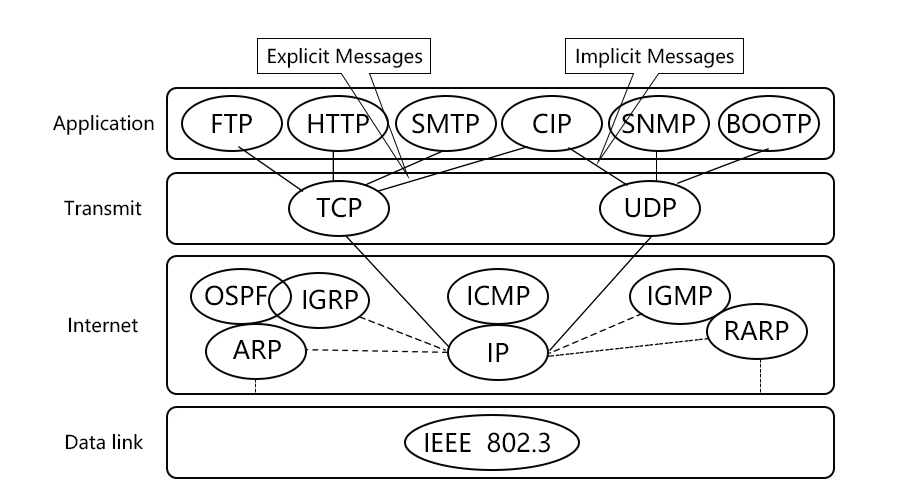

EtherNet/IP

technology is a clever combination of CIP technology and Ethernet technology

based on standard TCP/IP protocol. It only embeds CIP encapsulation protocol in

the data part of TCP or UDP packets. The main task of encapsulation protocol is

to define and standardize how to Encapsulate and transmit t-layer protocol

messages, and how to manage and utilize the underlying TCP/IP connections to

play a role.

EtherNet/IP

uses an efficient and flexible data exchange model - producer/consumer model.

The producer is the originator of the data, sending a packet to the network

carrying a "unique" identifier indicating the content of the data.

The consumer is the recipient of the data, and any interested consumer can

obtain the required data from the network through the identifier, so that

multiple consumers can receive and use the data. EtherNet/IP packets are mainly

classified into implicit messages and explicit messages. Implicit messages

mainly transmit some real-time I/O data, functional security data and motion

control data, and explicit messages.

Mainly

to transfer some configuration, diagnosis and other data. EtherNet/IP is based

on standard Ethernet technology. The whole process of data transmission of

Ether-Net/IP is shown in Figure 1. It uses UDP protocol to transmit implicit

messages and map UDP packets to IP multicast transmission. I/O exchanges

strongly support the producer/consumer model. And use TCP's flow control and

point-to-point features to transmit explicit messages over the TCP channel.

Figure 1 EtherNet/IP protocol architecture diagram

2. Ethernet

performance analysis

Ethernet is initially used in the field of office automation, and its MAC layer uses CSMA/CD (Carrier Sense Multiple Access/Collision Detection Protocol). When the network load is high, data transmission will be delayed, resulting in “uncertainty. "And this "uncertainty" is a taboo in the field of industrial control. Therefore, in the early development of industrial Ethernet, many people held a questioning attitude, which greatly restricted the development of industrial Ethernet.

However, technology continues to advance, with Ethernet

communication rates increasing from the initial 10 MB to today's 0.1 to 10 GB.

With the same amount of traffic, an increase in the communication rate means a

reduction in network load, and a reduction in network load means a certainty

improvement. According to relevant tests, Ethernet does not basically conflict

when the network load does not exceed 36%; when the load is less than 10%, the

10 MB Ethernet collision rate is 1/5/5, 100 MB Ethernet. It is 1 time / 15 a.

The full-duplex communication method further avoids conflicts. In addition, the

rapid development of Ethernet switch technology has brought new opportunities

to solve the uncertainty of industrial Ethernet. The switch can filter the data

transmitted on the network, so that the data transmission between the nodes in

each network segment is limited to the local network segment, and the chance of

collision of the data packet is fundamentally reduced to zero, and bandwidth of

other network segment is not occupied, reducing the network load of all network

segments and backbone networks.

At the same time, many manufacturers are working on network

accessories such as Ethernet network adapters, connectors, cables, hubs,

switches, etc for harsh industrial environments to improve the network's anti-jamming

capability and reliability. These all provide technical possibilities for Ethernet to be

directly used for communication between industrial devices.

For example, Shenzhen Lianrui Electronics Co., Ltd. (LR-LINK) launched a new product: LRES3004PT-four ports Gigabit wide temperature industrial Ethernet network card, which uses Ethernet power management technology such as energy-saving Ethernet and DMA integration, four ports all support remote wake-up function (WOL), can work in industrial environment of -40 ° C ~ 85 ° C, is the first real wide temperature industrial network card of Shenzhen Lianrui (LR-LINK). With customized industrial network cable, it can lock the cable and network port more firmly, effectively solve the problem of unstable connection between the network port and the network cable, and is also compatible with ordinary cable.

It has been shown at the Guangzhou Industrial Automation

Exhibition (SIAF 2019) and the Shanghai Machine Vision Exhibition (Vision China

2019), attracting many customers to communicate. Excitingly, the LRES3004PT

will also be displayed at the Computer Show COMPUTEX TAIPEI 2019 from May 28th to June 1st. Address: Booth No. K0204, 1st Floor, Nangang

Exhibition Hall, Taipei World Trade Center. You are sincerely welcomed to visit and exchange

guidance.

3.Performance of EtherNet/IP

In Ethernet,

TCP is a link-oriented protocol that provides reliable data transmission

services; UDP is a protocol without a link-based that can easily and quickly

deliver datagrams, but can’t guarantee if the datagrams arrive at the

destination device safely. EtherNet/IP uses Ethernet UDP to deliver real-time

data, and TCP delivers non-real-time data such as configuration and

diagnostics. To ensure the reliability of real-time data, the EtherNet/IP

protocol adds a series of measures, for example, each time transmits data,

header and serial number is increased, each time sends a datagram, the serial

number is incremented once, and the receiver passes the serial number

In the

EtherNet/IP network, the following two indicators are used to evaluate network

performance:

①

request packet interval (RequestedPacket Interval, RPI);

②

The number of packets sent per second (Packet per Second,

PPS).

RPI is an

important indicator of data periodic transmission. Regardless of the number of

nodes in the network, the source device sends data to the target device

according to the specified RPI period by the user. PPs = 1 000 ÷ RPI (ms). The

total PPS of a device = the total PPS of the source device + the total PPS of

the target device

According to

the performance of each device, the device manufacturer will make the minimum

RPI and maximum PPS of the device. When users evaluate network performance, the

total PPS of a device can't usually exceed 90% of the maximum PPS, and 10% of

the bandwidth is reserved for explicit message communication.

4.Conclusion

With the increase of Ethernet communication speed and the

development of full-duplex communication and switch technology, the certainty

of Ethernet communication is guaranteed, thus eliminating the main obstacles

that Ethernet directly applies to communication of industrial devices. Its

openness, high bandwidth and wide application make it have a huge advantage in

the industrial control field. Therefore, world-famous manufacturers and groups support

industrial Ethernet and developed different standards of industrial application,

and EtherNet/IP has become an important part of the international standard IEC

61158 (measure and control of digital data communications - fieldbus for

industrial control systems) and IEC 61784 (the set of profiles for continuous

and discrete manufacturing associated with fieldbuses used in industrial

control systems), It provides a complete network solution for the field of

automation communications, including the latest technologies of current automation

field such as real-time Ethernet, distributed automation, motion control, and

network security.

The EtherNet/IP adopter producer/consumer model greatly

increases the efficiency of EtherNet/IP device communication. Based on standard

Ethernet , it means that its industrial users can directly benefit a lot from

the continuous innovation and low cost of standard Ethernet technology itself. Its

performance will get better with other Technologies of Ethernet ,such as

information security technology, high-speed transmission technology, and

high-speed switching technology and etc. Therefore, EtherNet/IP will become the

mainstream of the new generation of industrial networks.

Shenzhen Lianrui Electronics Co., Ltd. is a technology-based enterprise specializing in R&D, production, sales and service of Ethernet adapters. It independently develops products based on mainstream solutions such as Intel, Marvell, and Broadcom, and is widely used by enterprises, government agencies, and telecom operators at home and abroad. Products serve the fiber to the desktop, IDC room, cloud computing, industrial automation, machine vision, education, medical and other industries. The company always adheres to the business philosophy of “professional excellence, quality and future”, and provides high-quality Ethernet adapter solutions for users with professional technology.